Where are magnets used?

Magnets and electromagnetic devices are all around us! They are in our homes, in our cars and at our workplaces. You will have used items that have magnetism probably without even considering it.

Magnets have many purposes that a lot of people may not have ever considered before. A magnet (or electromagnet) is a material part or assembly that creates a magnetic field that can be used to create a pull force, repulsive force, a torque or another response to a magnetic field (e.g. triggering a sensor) but where are magnets used?

When you opened then closed your fridge or freezer door, did you notice the magnetic strip that keeps the door sealed closed? Your handbag, smartwatch charger pad or tablet protective cover - the pull force you feel to clamp securely in place is due to magnets. Your hairdryer, washing machine, bathroom extractor fan – anything with a rotating part – they all use electromagnetic circuits and some of those items may contain magnets.

Magnets are also used to keep you safe or to keep you moving - steering wheel sensors, seat belt sensors and fuel pumps can all use magnets. When you turn on your car audio system, magnets are used to create the sounds. Permanent magnets are also in many wind turbines to create electricity. There are endless uses of magnets in nearly every industry you can think of - a lot of which you may not have expected.

In this article, we’ll take a look into some of the products and industries where magnets may be used, both expected and unexpectedly. But first – what are magnets?

What are magnets made from?

There are different types of magnets made from different materials. Some materials are stronger than others.

They are all made from varying compound compositions (often from alloying processes or casting processes). Each grade is a little bit like a cake mix (different combinations of composition to give different qualities or attributes).

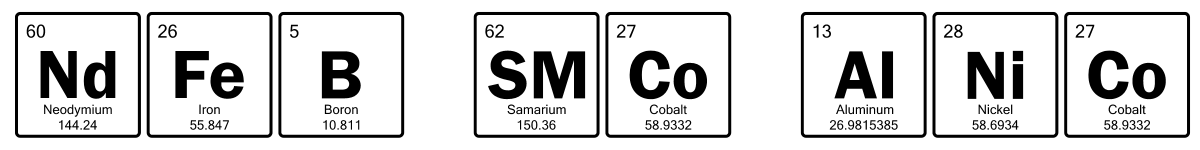

- Neodymium Iron Boron (NdFeB) – regarded as the main “rare earth magnet” and often called “Neo” – size for size, these are stronger magnets than AlNiCo, SmCo or ceramic/ferrite magnets. They are often a first choice of magnet.

- Samarium Cobalt (SmCo) – these are also “rare earth magnets” but these magnets can operate at much higher temperatures than NdFeB and also have better corrosion resistance than NdFeB magnets. They tend to cost more than NdFeB, but are a better choice for harsher or more extreme environments (e.g. cryogenic, aerospace, etc).

- Ferrite / ceramic magnets – these magnets do not cost as much as rare earth magnets to produce and do not corrode (the iron in them is already in an oxidised state) but they are not as powerful as the rare earth magnets. They are often used in motors, generators, loudspeakers, and applications where a weight and small size are not so important and/or where keeping cost lower may be prioritised.

- AlNiCo – Aluminium, Nickel and Cobalt magnets – these were the first ‘proper’ magnets (after magnetic steels). They can give very high magnetic output and can be used at extremely high temperatures – they can be used instead of the rare earth magnets in some applications, especially where you want to minimise output with large temperature changes. They can be used in extreme environment sensor applications. They are also easier to magnetise and demagnetise, making them great for use in magnetic switching applications (such as magnetic workholding and pick-and-place applications).

Now you understand that there are a wide variety of magnets, other than just the ones you hang on your fridges, how do they even work?

How do magnets work?

Every atom has electrons and these electrons all spin, creating tiny magnetic fields. In most materials the spins cancel out, so no net magnetic effect is noted. In other materials, the electron spins combine to create a net magnetic field and the magnetic fields of atoms can group together and align to form magnetic domains.

Think of magnetic domains as a bit like miniature magnets within a material. In most materials the domains are randomly pointing and so any magnetism from them is cancelled out by the surrounding domains, leaving a non-magnetic material. In other materials, the magnetic domains can be aligned in the same direction (using an externally applied magnetising field), causing a net magnetic field afterwards, resulting in a noticeable magnetic performance, which we know as a magnet.

When another magnetic or ferrous object enters this magnetic field, it experiences an attractive or repulsive force depending on the orientation of its own magnetic domains, demonstrating the fundamental principles of magnetism.

If you didn’t already, you now know how magnets work and what they’re made from, so let’s consider where these magnets are used.

Where are magnets used?

Automotive

Magnets have an incredibly wide range of uses in the automotive industry. To mention a few, there are magnets for ABS sensors, seat belt sensors, steering wheel sensors, KERS regenerative braking, motors for moving windows, etc.

There are magnets in door locks, air bag sensors, folding mirrors, windscreen wipers and speed sensors among many more, not forgetting for cruise control, air conditioning & climate control and once again, in the speaker systems!

Magnets can be used in steering wheels to track its position and speed of rotation and, with electric vehicles, magnets are used in the motors to power the drivetrain. There are even magnets for holding your headliner securely in place!

And have you ever noticed how people effortlessly stick tracking devices on cars in the movies? Those are magnetic!

Click here to view our full range of magnetic solutions for the automotive industry

Aerospace

Unsurprisingly, magnets are used in aerospace as well. They are used in actuators in helicopters at the top of the propellors and the tail at the back to control pitch, roll and rotation.

In airplanes, they are used in the cockpit on the navigation controllers (fly by wire systems), the motors for the slats on the wings of the plane, in fuel pumps and in engine driven generators/engine starters.

Magnets can be used to trigger something to work, by sensing something nearby or being used to actuate a part. They can also help detect/sense and/or measure and/or activate. They can be used in force and torque production, proximity measuring and in the creation of movement and securely clamping.

Click here to view our full range of magnetic solutions for the aerospace industry

Lifting magnets

Lifting magnets are used in production and in warehouses to lift heavy, ferrous materials, such as round bar, sheet and plates safely around the workplace.

A lot of the customers we supply often have custom requirements. In any such specialized application, we always have to ensure the lifting magnet can achieve at least a 3:1 safety factor at all times.

Factors to consider include the material type, material thickness, surface finish, air gap, material shaper/profile, lifting requirement, and temperature.

Lifting can be achieved using magnets, electromagnets and even electro-permanent magnets. Magnetic performance can be turned “on” and “off” manually, electronically, and even with the use of air! We also have lifting systems that are failsafe (won’t drop a load) even if the electricity or air supply is removed. We have manual lifters that can lift up to 2000kg, even with a 3:1 safety factor!

Click here to view our full range of magnetic lifters

Foreign Body Removal in Food Production and Pharmaceuticals

Food production companies use magnets to remove ferrous material from a flow of product and they also use metal detectors to detect any metal material (ferrous and non-ferrous). This allows methods for any company to separate contaminant metals from their food products at multiple stages in their production processes. This separation process is to ensure the food that ends up on your table is free from such unwanted contaminants!

Effective separation systems are a vital part of HACCP plans, providing protection for consumers, process equipment, and brand or retailer reputation.

Our products help prevent the need for product recalls, so the food on the shelves of the supermarket is clean and safe for you. They are similarly used in the production of pharmaceuticals, so these too are kept safe from contaminants, and they can be used in the plastics industry (removing contamination from pellets for example). Want to know more about how these contaminants are removed from food and pharmaceutical production lines? You can watch this animation here of products we manufacture to help food companies keep you safe!

Click here to view our full range of magnetic separation and detection products

Plumbing and Heating

Plumbing and heating is another big industry in which magnets are used. Similarly to the way magnets are used in foreign body removal for the food production industry, magnets are also used to filter out ferrous or magnetically susceptible materials out of the boiler system.

Coolant filtration – cleaning industrial fluids

The swarf in your machining fluids may be very magnetic (mild steel) or weakly magnetic (stainless steel, carbide, etc.). Rather than let the swarf be caught in filter bags which then end up in landfill, by using a magnetic filter system, you can capture the contamination and remove it from the coolant. You can then easily recycle the captured material and, by removing it before it gets to the filter bag, you don’t need to change the bag as often (less landfill and less cost). Plus, it can prolong the life of the coolant.

It isn’t just coolant than can be magnetically filtered and cleaned. Any fluid (liquid or gas), as long as it is compatible with the materials we have used to produce the filters, could be passed through the magnetic filtration units to capture and remove the ferrous material. This may involve chemical manufacturing, water, various acids and alkalis, oils, hydrocarbon gases, and more.

Click here to view our full range of magnetic filtration products

Fabrication magnets

Machining parts often uses magnets to hold those parts in place during machining. Magnetic chucks, welding aids, magnetic V-blocks, etc. are all used to facilitate production of ferrous parts. Magnets are used to safely move items around, such as lifter magnets, ESPM and PSPM. These are vital magnets to manufacturing processes which many people rarely get to see.

Wind turbines

Ever wondered how wind turbines move to generate power? Whilst it is true that the wind itself is what helps the turbines to rotate and generate power through converting kinetic energy to electrical energy, they often contain permanent magnet generators! Magnets play a huge role in the functionality of wind turbines and there are many magnets in one turbine alone. Who would’ve guessed!

Sensor magnets

Magnets are used in alarms too! If you have security alarms in your home, you may notice a beep whenever you open your front door. This is because they work on sensor magnets to send messages between the doors and alarm system, which ultimately protects your home!

Sensor magnets work by triggering a reed switch or hall effect device – whether this be home security systems or when cars identify an occupied seat without the seatbelt being plugged in. Sensor magnets can be used to detect position and even speed. The number of applications across so many industries is vast!

Loudspeakers, hairdryers, mobile phones & other electronics

Magnets are used in a wide variety of electronics.

In loudspeakers, there are (usually) ferrite or NdFeB magnets (discs or rings) within the speaker which interact with the powered coil on the cone to allow the cone to move and project the sound from the speaker. Magnets are an essential piece of the speaker which allows it to function. They also help keep shipping lanes safe – think foghorns!

The motors inside hairdryers use magnetic technology to work, similar to the way washing machines do too! Anything that uses electricity to rotate utilises magnetic fields – and a permanent magnet could be part of that technology!

There are a variety of little magnets hidden inside of your smartphones. Magnets are used in the speakers of the phone – the same principles of how they work in loudspeaker systems!

Reading this article on a laptop or tablet? Some older hard drives contain magnets, the speakers contain magnets, and the protective casing for your tablets, such as flip cases, have magnets to help keep them shut.

Click here to view our full range of magnetic solutions for audio applications

Shop displays

Shopping in supermarkets is a lot easier with hanging signs on each aisle, helping you find what you need. Next time you are in a shop, have a look around you at the displays – notice any magnets holding banners into place? These types of magnets are used from a variety of displays in many industries! You can have a look at our neo hook magnets and flexible tape and sheet here that are often used for this very purpose!

Railways

Magnets are used in some railway systems, whether it be on the tracks or even in the trains themselves! There are automatic warning system (AWS) magnets on tracks for example, and on another scale, MagLev trains – magnets are used for frictionless levitation for high speed travel.

Electromagnets for safety, and more

There are two types of electromagnet – energise-to-hold and energise-to-release. They are often used in safety-related applications such as security and access control applications. For example, they can be used in machine guards to keep the doors closed whilst the machine is carrying out its milling/grinding operations.

carrying out its milling/grinding operations.

Additionally, electromagnets are used in fire doors - they release the door when a fire alarm goes off.

They can be used in theatres - to keep the curtains in place until they are released to end the show! Next time you’re at the theatre, when the curtain drops, remember the electromagnets allowed that to happen.

Click here to learn more about electromagnets and see our range of products

Furniture

There may be many magnets in your home that, at first glance, you may not be aware of – from speakers in your radio, tv and smart hub, to the magnetic tape that seals your shower door closed, but have you considered latches and catches? They can be added inside furniture to keep doors closed.

You may have a magnetic knife rack in your home (perhaps that's an obvious one)... but what about the seals in your fridge door – they are magnetic and help keep the seal airtight!

Have you considered the use of magnets in equipment such as exercise bikes? Some work by a magnet causing an eddy current effect to resist its rotation (the same idea with roller coaster brakes).

The future of magnets?

As we have shown, there are many, many purposes in which magnets are used. There are so many uses for magnets, many of which you will reliably use every day.

Magnets are used to help make many of the products you use every day (whether inside the products or used in their manufacturing processes).

When you consider how technology has changed over the last 100 years, there are so many ways in which magnetics have been used as part of those changes and improvements. As development in technology continues in new and unexpected ways, who knows where we’ll be surprised to learn where magnets are being used in 100 years to come.

UK

UK