Micromag Magnetic Filter

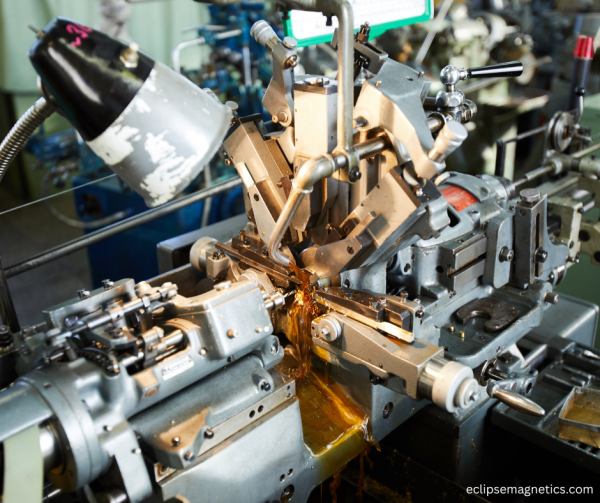

Compact, high-performance grinding coolant filtration systems (flow rates up to 150 litres per min.)

Industrial filtration is a complex topic, on which there are many different opinions. But there is one thing that all experts agree on: effective filtration is essential in any industrial process.

Not only does filtration help to extend fluid life, but it can also improve the quality of the final product, as well as reducing machinery downtime.

Whilst some filtration systems use barrier methods such as cartridge or bag filters, others use magnetics to attract and remove ferrous contaminants from fluids. But how do you know which type of filtration is right for your application?

In this article, we’ll explore the different methods of filtration in more detail, as well as taking a closer look at whether magnetic filtration could benefit industrial applications.

Contamination is a challenge in every industry, and it can enter the production process in many ways. Whether it originates from external sources or from within the manufacturing process itself, such as wear particles from machinery operation or waste created by the fabrication process, contamination can cause significant problems if it is not effectively removed.

Without filtration, contaminated fluids will have a dramatically reduced lifespan. Not only does this result in increased costs to the business, but also an increase in downtime for maintenance to be performed.

In machining processes, contamination can also lead to a reduction in quality of the final product. For example, ferrous contamination could scratch the surface of fabricated steel products, resulting in rejection by quality control.

Effective filtration should keep fluids clean, extending their service life and protecting the machining process. In turn, this can increase both productivity and profit margins for the business.

View our full range of magnetic filtration products here

Traditional methods of filtration have been used for many centuries. In fact, it is thought that the most basic methods of filtration date back to 2,000 BC, when the Ancient Egyptians used plant material to purify water.

In today’s world, we are lucky to have a variety of options when it comes to filtration, and this extends to industrial filtration.

When we talk about traditional methods of filtration, we’re referring to barrier methods, such as cartridge filters or bag filters. These types of filters enable the fluid to pass through a physical barrier, where larger particles are removed.

However, there are some disadvantages to barrier filters, which must be weighed up carefully when making a decision on the right type of industrial filtration method for your application.

Let’s take a look at some of the challenges that are faced when using traditional methods of filtration.

One of the biggest challenges that is faced when using traditional methods of filtration is that they are not always effective. As this method uses a physical barrier to remove contamination from fluids, only contamination that is larger than the micron rating of the filter will be removed. This means that smaller particles remain in the fluid, and contamination will continue to build up.

Another challenge with barrier methods of filtration is that regular maintenance is required to change the filter medium. This maintenance often requires downtime, involving shutting down the machinery so that the filter medium can be changed.

Not only is this inconvenient for the business, but it can also be costly, requiring manpower and a loss of productivity during the maintenance period.

When using traditional methods of filtration, there is always a chance that the filter could fail. For example, a paper filter could tear, allowing contamination to flow through the filtration system and causing damage to the machinery.

This then leads to further downtime, as well as the potential for heightened rejection rates, increasing the costs to the business.

When you have a high PPM (parts per million) or high number of particles in your machine fluids, this increases the friction between the cutting tool and the surface of the component when machining.

This friction leads to wear, damaging your cutting tools and other critical machine components. So, with traditional filtration methods which are less effective, you’ll typically find that your machinery wears faster, leading to a higher rate of replacement.

Finally, barrier methods of filtration require consumable parts. The filter medium needs to be replaced regularly to remove the build up of contamination and prevent failure. The used filters are often sent to landfill due to the contamination that has been collected, and a new filter medium is fitted.

With businesses placing an increasing importance on sustainability, moving away from traditional filtration methods is one way to reduce your consumable parts and prioritise the environment.

Magnetic filtration provides an innovative improvement to traditional filtration methods, offering some significant benefits to businesses. But what is magnetic filtration and how could it help your business?

Magnetic filtration involves using magnets to remove ferrous, ferritic, martensitic and paramagnetic contamination (materials that are attracted to permanent magnets – we’ll call them all ‘ferrous’ going forward) from fluids. Fluid is directed through the magnetic filter to flow around magnetic rods which attract such ferrous contaminants. The ferrous particles then stick to the magnetic rods and remain there until it the rod is cleaned.

Unlike with barrier methods of filtration, there are no consumable parts – the magnet can simply be cleaned and replaced, enabling many years of continuous filtration.

There are many varieties of magnetic filtration system available, from small filters which require manual cleaning to automated filtration systems which are suitable for 24/7 operation with minimal manual intervention required.

Magnetic filtration systems offer many benefits to businesses, from extending fluid life to reducing maintenance requirements. Let’s take a look at some of these benefits.

Fluids such as oils, coolants and cutting fluids rely on purity for effective operation. When contamination enters the fluid, it significantly shortens its lifespan, meaning that the fluid will need to be replaced sooner.

Magnetic filtration is an effective method of removing ferrous contamination from all types of industrial fluids. Continuous removal of contamination can help to extend the life of fluids, in turn reducing operating costs and maintenance requirements for the business.

Not only is downtime an inconvenience, but it can significantly impact on the productivity and profitability of a plant. Maintenance is one of the leading causes of downtime, so reducing maintenance requirements is a priority in every industry.

Magnetic filters have a higher collection capacity than many traditional filtration methods such as paper filters, meaning that maintenance intervals can be extended. This helps to reduce overall downtime, enabling the plant to be more efficient and productive.

Where there is non-magnetic contamination present, it is always recommended to retain the existing bag filter system but have it located always after the magnetic filter to help capture these particles (they can be captured to a degree amongst the collected ferrous contamination on the magnetic rods). The result of this is that you have improved capture but, since the magnetic filter removes the ferrous contamination, the bag filter takes longer to get full which then prolongs intervals between bag filter maintenance, reduces bag filter replacement costs and improves productivity.

Not only that, but there are also automated magnetic filtration systems available, which automate the cleaning process. This means that plant shutdown is not required, and 24/7 operation can be maintained, prioritising your productivity. There are also methods to have magnetic filters in parallel to allow one to be cleaned whilst the other is still in use to prevent downtime whilst manually cleaning.

After the initial installation, many engineers find that their maintenance requirements are significantly reduced with magnetic filtration systems. The clean tanks stay clean because the ferrous contamination is caught and removed so it doesn’t settle in the tanks leading to having to be dug out periodically.

Whatever you’re machining, surface finish is essential. Damage such as scratching, which can be caused by ferrous contamination, can lead to increased reject rates, reducing profit margins.

Magnetic filtration systems effectively remove even the smallest particles of ferrous contamination, protecting the purity of your machine fluids and helping to prevent damage to the surface finish of machined products. Magnetic filtration systems are capable of removing sub-micron sized particles.

Highly contaminated fluids increase the level of friction between a cutting tool and the component surface. This leads to increased wear on the machine tools, leading to frequent replacements being required.

Magnetic filtration removes almost 100% of ferrous contamination, reducing friction and helping to extend the life of your machinery. This in turn will reduce downtime requirements, as well as minimising your costs.

With an increasing focus on Net Zero, sustainability has never been more critical to businesses. Whatever industry you’re operating in, the pressure to reduce CO2 emissions and do your bit for protecting the planet has never been higher.

Magnetic filtration systems have no energy requirements, so they won’t contribute to your CO2 emissions. This is because they use the power of magnetics, rather than electricity (the exception being the automated systems but they can be set-up to optimally clean to maximise overall efficiency).

Not only that, but they also contain no consumable parts, such as disposable filter medium. This means that there are no disposal costs, and nothing is being sent to landfill. With magnetic filtration, you can rest assured that you’re doing your part for the environment, whilst also doing the right thing for your business.

The magnets collect the ferrous contamination which can be manually or automatically cleaned and collected – the contamination, by not being held within other media, can be sold back to recyclers to re-enter the production of the original materials which can help conserve the planet’s resources and can count towards your company’s carbon footprint reduction.

And filtration fluids that are kept cleaner can then be kept because the can safely last longer. This reduces the need to use as much fluid volume annually, which not only reduces your costs but also reduces the amount of fluid having to be recycled or disposed of.

It’s easy to compare the cost of a disposable paper filter with the cost of a magnetic filtration system and choose the cheaper option. However, it’s important to also consider the long-term cost of each option.

Whilst the initial costs of installing a magnetic filtration system will usually be more expensive than a simple paper or cartridge filter, with magnetics you’re paying a one-off cost. This cost is then offset by the savings you can make in maintenance requirements, downtime, extended fluid life, reduced rejection rates and energy savings over the proceeding years. In some applications the return on investment from using a magnetic filter can be extremely quick.

View our full range of magnetic filtration products here

Magnetic filtration systems can be installed on almost any application which deals with fluids, such as oils, coolants and cutting fluids which may be at risk of ferrous contamination. For this reason, magnetic filtration systems are often used in industries such as:

Our magnetic filters can also be used to filter out ferrous contaminants from foodstuffs (we provide food safe magnetic filtration solutions). We also have magnetic filtration products for domestic and industrial heating systems, cooling systems and heat pump systems. Where there are fluids (liquids and even gases) we probably have a solution to your magnetic filtration needs (including ATEX requirements and also handling many corrosive fluids).

Magnetic filtration systems fall into two main categories: those that use manual cleaning methods, and those that are automated. Let’s take a look at each of these types of magnetic filtration system.

Manual magnetic filtration systems rely on manual cleaning by an operator when the magnetic rod becomes full. The rod is then removed from the application and the magnetic core is removed. Once the magnetism has been removed, the collected contamination can then be easily cleaned from the filter.

Magnetic filters that rely on manual cleaning are typically the lower cost option and are ideal for use in smaller plants. This type of filtration system does not require a power source for operation or cleaning, meaning that they do not consume any energy. This is welcome news to companies that are looking to increase their sustainability, or who might be working towards Net Zero targets.

Our manual magnetic filtration systems include Micromag and Filtramag+.

For larger plants, or where manual maintenance is undesirable, for example in hazardous environments or 24/7 operation plants, automated magnetic filtration systems are often the preferred solution.

Automated magnetic filtration systems have a self-cleaning feature which automatically removes contamination from the magnetic rods at preset intervals. This means that minimal manual intervention is required. Many automated systems also enable fluid recovery and reclamation of ferrous particles which can then be recycled, further enhancing your sustainability.

Our automated magnetic filtration systems include Automag and Autofiltrex.

Barrier filtration methods such as paper or cartridge filters will always have a place in industry, as long as there is contamination that needs to be removed.

However, magnetic filtration provides an innovative way of removing ferrous particles from fluids at a sub-micron level. Rather than being restricted to only filtering particles that are unable to pass through a barrier filter, a magnetic filter will remove any contamination that is magnetic, whatever its size.

Rather than replacing traditional filtration methods completely, magnetic filtration has the ability to compliment existing filtration, enhancing its effectiveness and helping to extend machinery life. If you have ferrous contamination and you use barrier filters, you should additionally place a magnetic filter before that barrier filter – you will soon note that you don’t need to replace the barrier filter as after but you will also start to have cleaner fluids and will not have to replace the fluids as often either, leading to less downtime and efficiency gains.

Magnetics has revolutionised filtration in many industries, reducing ongoing costs, minimising downtime and enabling companies to reach their long-term sustainability goals.

However, it’s important to note that magnetic filtration may not be right for every business. The benefits and disadvantages of each type of filtration method should be carefully weighed up before an informed decision can be made.

It is also important to note that a magnetic filter should not be viewed as a direct replacement to an existing barrier filter – it is a compliment to that barrier filter that will give additional cost savings and efficiency gains to the customer. A combination of both traditional filtration methods and a magnetic filtration beforehand is the most effective approach. The cost savings some customers have experienced has paid for the magnetic filter they bought in quicker timescales than even they had envisaged.

If you need assistance in selecting the right filtration system for your application, our filtration experts are on hand to help. Give us a call on 0114 225 0600 or complete our online enquiry form here.