Armature Plates for Electromagnets

To fit both hold and release electromagnets

When activated provides a release action

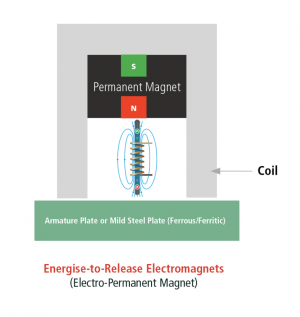

Overview - Energise-to-Release Electromagnet

Energise-to-Release Electromagnets are electro-permanent magnetic assemblies designed for secure clamping with controlled electrical release. They combine a permanent magnet with a solenoid (wound copper coil) housed within a high-permeability iron assembly, delivering high clamping forces with low magnetic losses and excellent operational efficiency.

In their default state, these units provide a secure magnetic hold without the need for electrical power. Electrical energy is only required to release the magnet, making Energise-to-Release Electromagnets an energy-efficient and fail-safe solution for safety-critical and industrial applications. When power is removed, the magnet automatically returns to its clamped (ON) state.

The magnet assembly is housed in a sturdy iron cylinder with a bright nickel-plated finish, passivated for durability and body mounting. This robust construction makes the units suitable for demanding environments where reliability, repeatability, and long service life are essential.

Each Energise-to-Release Electromagnet is supplied with a matching armature (keeper) plate, engineered to maximise pull force and ensure consistent magnetic contact. Armature plates feature a central tapped mounting hole on the rear face, allowing secure installation.

Electrical & Performance Characteristics

Depending on the unit size, Energise-to-Release Electromagnets are available with:

Supply voltages: 24V DC or 240V AC

Duty cycle: S2 (short-time duty)

Ingress protection: IP54

Electrical connections: Hirschmann connectors or Hirschmann-style connectors

These electromagnets offer maximum pull force ratings from 285 N up to 471 N (approximately 28 kg to 47 kg, depending on size and application). Actual holding force achieved will depend on surface condition, alignment, and the use of the recommended armature plate.

Typical Applications

Energise-to-Release Electromagnets are designed for controlled clamping and release in applications where safety, reliability, and energy efficiency are critical, including:

Door locking systems for access control and security

Fire door holding and release mechanisms

Medical devices and equipment

Automated packaging and feeder systems

Pick-and-place and handling equipment

Power generation and industrial machinery

Advantages of Energise-to-Release Electromagnets

Fail-safe operation – clamps securely when no power is applied

Energy efficient – electrical power required only to release

Secure holding force without continuous current

Compatible with ferrous surfaces (maximum pull achieved with armature plates)

Check out our free guide here to compare between Electromagnets and Permanent Magnets

Find out more about Electromagnets & Electromagnetism.

| Product Number | Connector | Current (ma) | Diameter | Height | Weight (g) | Fixing Point |

|---|---|---|---|---|---|---|

| M52177/240VA | Hirschman | 50 | 35 | 81 | 354 | M5 |

| M52178/240VA | Hirschman | 40 | 50 | 97 | 880 | M5 |

| M52177/24VDC | Hirschman style | 50 | 35 | 78 | 352 | M5 |

| M52178/24VDC | Hirschman Style | 40 | 50 | 874 | 94 | M5 |