Ultralift E Magnetic Lifter

Our brand new high performance and cost-effective magnetic lifter

More and more businesses now have active continuous improvement programmes. Many production and engineering companies are continually looking at investing in cost-effective solutions that offer efficiency improvements and, at the same time, make the workplace safer for employees.

More and more businesses now have active continuous improvement programmes. Many production and engineering companies are continually looking at investing in cost-effective solutions that offer efficiency improvements and, at the same time, make the workplace safer for employees.

For factories, workshops, warehouses or stockholders requiring movement of steel-based profiles, the Ultralift E magnetic lifter is one such solution. It offers tangible gains for minimal investment.

Ultralift E is a magnetic lifter suitable for lifting ferrous blocks, sheets, flat or round bar. It offers clear advantages in comparison to more traditional lifting methods such as slings, chains, hooks, and grabs. Using permanent magnetic technology, it requires no consumable power source and has in-built safety mechanisms to ensure fail-safe operation.

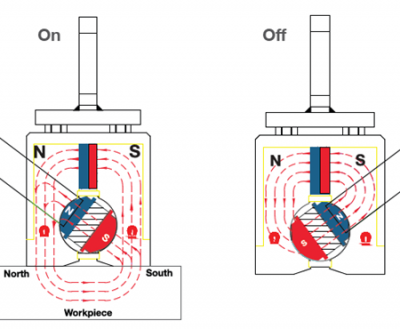

Ultralift E is simple to operate, requiring only single-face engagement with the load. To engage with the load, simply rotate the handle to the on position. This changes the direction of the magnetic flux, which then engages the load. When the handle is rotated to the off position, the magnetic field is diverted away from the load and allows its release. A safety lock on the handle prevents it from being released during lifting, and a 3:1 working load limit (WLL) safety factor negates the risk of user error.

Ultralift E is simple to operate, requiring only single-face engagement with the load. To engage with the load, simply rotate the handle to the on position. This changes the direction of the magnetic flux, which then engages the load. When the handle is rotated to the off position, the magnetic field is diverted away from the load and allows its release. A safety lock on the handle prevents it from being released during lifting, and a 3:1 working load limit (WLL) safety factor negates the risk of user error.

Learn more about the Ultralift E Magnetic Lifter here

* Directives from LOLER, PUWER, ASME B30.20, and HSE recommend regular checks and annual servicing.

** Always check that the load weight, material, surface finish, and dimensions are compatible before engaging the lift (see product manual). Test lifts should be undertaken.