Mould Tool Manufacture

Company Name: TRP Sealing Systems Ltd

Location: Hereford

Eclipse Product Installed: Bespoke Premium Power Matrix System

Industry: Mould Tool Manufacture

Our Client

TRP Sealing Systems Ltd specialise in supplying seals, gaskets and technical mouldings for demanding environments and advanced applications. Their customer base includes some of the world’s most renowned and respected blue chip engineering customers, working with market leaders in sectors including general engineering, automotive, food and drink, electronics and medical equipment.

The Challenge

In order to offer their customers shorter lead times on products, the company has recently set up a purpose-refurbished tool room to carry out the manufacture of mould tools. As part of this, TRP Sealing Systems Ltd has invested in a new ‘WELE Large Bridge’ machining centre from 2D CNC Machinery, which will enable them to integrate larger mould tool operations in house. As the largest machine in the country of this manufacture, the WELE LB 421 has a 4000mm by 2000mm table with a load capacity of 15 tonnes. Located in Hinckley, Leicestershire, 2D CNC Machinery Ltd is the sole distributor for WELE products in the UK.

As part of the mould tool manufacturing process, TRP Sealing Systems Ltd required an effective method of securing steel plates. Thin plates of good quality steel are used in the manufacturing process, ranging in size from between 16mm to 30mm thick. Plate dimensions range from 860mm by 830mm to 3900mm by 1750mm.

TRP Sealing Systems required an application that would allow them to accurately machine both faces of the steel plate and all edges. In order to avoid inherent warping in the plate, which carries the possibility of compromising the precision of the tools, the plates need to be secured in such a way that they are perfectly flat when processed.

One solution would have been to clamp the plate down using bolts, but this method raised a number of obstacles. Manual clamping would require a series of holes to be drilled in the plate in order to ensure that it was held in place securely. This would also cause unnecessary problems when it came to loading components and repositioning the workpiece to gain access to all faces during the cutting process.

The Solution

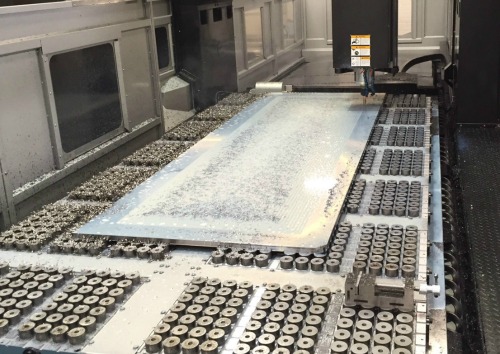

Eclipse Magnetics was able to offer TRP Sealing Systems Ltd a solution in the form of a bespoke electro-magnetic chuck; a magnet bed supplied in 14 sections. The overall size of the Power Matrix Milling system is 4,000mm x 2,000mm x 66mm high, which fills the table. Each chuck has different groups of individual magnetic islands 50mm x 50mm in size, which are placed in position in order to provide clearance for drilling and milling. This type of chuck also allows the connections to the magnets to be situated inside the recesses between the magnets and run along the rear of the table.

Eclipse Magnetics supplied the magnets including a fixed, full steel, working top plate that would provide the known height for the components, ensuring that the Z axis is constant in all instances. A solid platform was created using 14 chucks, including controllers to switch all chucks in set zones. This allows the operator to effectively switch on the area of the platform that is required, and can be removed by using a key switch inside the controller. This set up also allows cable runs between the chucks to the rear edge of the table, providing sufficient protection from damage. Small gaps between the chucks are covered with stainless steel cover plates in order to protect the cables from coolant and swarf ingress.

Datum location for all sizes of plates has also been provided, which allows the operator to position the plates according to a centre point on the table. This ensures that when the part is in position, the work holding will provide clearance for all through holes and back facing applications for the range of plate sizes, without machining the chucks themselves.

The Power Matrix system provided employs the latest permanent electro method of switching. This, combined with the superior Eclipse Alcomax magnets and the high coercivity, high energy Neodymium magnets, means that the extreme power generated by the chuck is completely failsafe. In order to activate or de-activate the chuck, only a split second of power is needed, and no power is needed or used during the work holding or machining phases. This offers the advantage of maximising safety, saving energy, eliminating top plate deformation and eliminating the loss of magnetic power over time.

The Power Matrix incorporates high intensity neodymium magnets to ensure an extremely robust, high performance clamping system, ensuring accurate cutting of the steel to achieve precision results. Because no time is wasted fitting and positioning clamps, the Power Matrix maximises feed rates and provides consistent uniform clamping. The chuck eliminates vibration during the machining process, which can affect the accuracy of the machining. Reduced vibration and chatter extends insert and tool life, and improves the surface finish of the product. The Power Matrix also allows 5 side access to the workpiece, therefore eliminating repositioning time and increasing productivity.

Although the Power Matrix can be supplied with pole extensions, TRP Sealing Systems Ltd opted to make the pole extensions themselves, enabling them to take the power from the magnet up by 30mm. Eclipse Magnetics provided intensive support and guidance for this process, ensuring that they were able to accurately drill through the steel plate without damaging the magnetic table. TRP Sealing Systems Ltd also plan to use resin to fill in the gaps between the pole extensions which will make the Power Matrix easier to clean down.

John Urbanski, Engineering Manager at TRP Sealing Systems Ltd said: “The Power Matrix has enabled us to not only reduce our set up time significantly, but also to ensure that the tool manufacture is of the highest quality possible. We chose this product because it was an extremely cost effective option for the quantity and quality of the magnets included, as well as the attractive delivery options. We were able to collaborate effectively with Eclipse Magnetics to ensure that the installation process was swift and efficient; everything went like clockwork!”

Find out more about Magnetic Workholding or contact us for more details.

USA

USA