With 100 years of experience in the design and manufacture of high performance magnetic systems, we supply critical magnetic equipment to some of the leading names in the most demanding industries. We are firmly established as a leading manufacturer and supplier of magnets and magnetic equipment.

Providing Competitive Edge with Magnetic Technology

You too can "Work Smart with Magnets", our business is making a difference to your business by applying magnetic technology. With our unrivalled magnetic products portfolio and wealth of expertise we can drive competitive edge into your business by reducing costs, increasing operational efficiency, improving safety or environmental benefits with magnetic innovation.

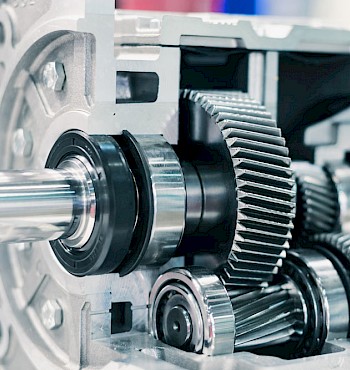

From simple everyday workshop challenges to complex hi-tech OEM projects, our magnets provide the solution. Our magnetic technology is applied in numerous sectors including Automotive Manufacturing, Aerospace, Food Processing, Precision Engineering, Pharmaceutical Processing, Oil & Gas, Steel and OEM Automation projects. As a leading UK magnet supplier, our magnets and magnetic products are also stocked by some of the world's largest industrial products distribution outlets.

In addition to the products highlighted on this website we have specialist divisions for Oil & Gas pipeline projects (Ultrafiltrex)and energy efficient heating system products (Boilermag) to serve those markets.

Group Strength - A Spear & Jackson Group Company

We are part of the world renowned Spear & Jackson Group. With a 250 year history, the Spear & Jackson Group is now a multi-national organisation with divisions covering garden tools, Bowers Group metrology equipment, Robert Sorby woodworking tools and as well as magnetics.

Made In Britain

We are approved members of the "Made in Britain" scheme. This enables us to carry the prestigious Made in Britain trademark on our UK manufactured products, which is widely accepted as a symbol of quality and reliability.

UK

UK